Friday, June 6, 2008

Self Evaluation

Andrew Feiter

Systems Engineering II

Over the past year I have been working on design for a robotic arm, my senior design project, for the MATEs competition. My project was only one part of the ROV that was going to compete in the competition in late April. My projects role in the overall scheme of the competition was for the design to be able to help complete the missions that were set down by MATES.

The final solution chosen to complete the tasks at the competition ( pick up rock crabs off the floor, grasp rocks attached to a vent pipe, and take the temperature of the surrounding water) was designed to perform all the necessary tasks. The design was contained in a polycarbonate housing to protect the arm and the gear system that powered it. The gear system was a simple worm geared system, that is it a motor, in this case a small DC motor, turns a shaft which then turns the worm gear which then turns the two helical gears connected to it, which turn the claws in opposite directions. The motor was designed to be sealed in a water tight compartment in the back of the housing, to help keep the motor waterproof and to give the ROV positive buoyancy. The claws were made of the same polycarbonate as the housing so they would be able to handle any collisions with any objects that the ROV would encounter during the missions. The arm was to be held together with a combination of screws and epoxy to help ensure a strong tight seal. The arm was to be attached to the ROV by nuts and bolts and was to sit centered on the ROV.

During the design process and construction phase of the project a couple of things changed in the design of the arm. The first and most noticeable was the addition of an extra set of claws. The extra set of claws was added at the end of the construction to help the arm grab objects that would sit lower than the claws that were positioned already on the arm. This was required because the arm design did not take into account the height of the objects off the pool floor. The new claws were made of hard pre fashioned plastic, an epoxy piece of polycarbonate which held a rubber grip for claw. Another discrepancy was the way arm was water sealed. In the original design the housing itself was supposed to keep the motor’s area watertight, however after testing it multiple times it was evident things had to be sealed another way. It was decided to use epoxy to seal all the areas water was leaking from in hope of sealing the arm.

While working on the project I encountered numerous success and failures. One of the success I encountered was in the very beginning of the project was getting all of my items ordered in a timely fashion. After going through the arduous of the ordering process it was a huge success to have everything ordered and in the process of delivery on timed after spending countless classes trying to find and order the items. Another success that I had while completing this project was when I finally assembled the whole project before the competition. For weeks on end I had been working hard to try to complete the arm, and when the final product was finally put together it was a great success in my eyes. The final success that I encountered during this project was when the motor and gear system worked when it was tested. When the preliminary testing went on the motor and gear system worked together proving the design worked. Along the way I also encountered numerous failures. The first of the failures was not getting my desired gears, which were made of steel and were industrial grade, this were not procured because of issues with the bid process. Another failure I encountered was the failing of the arm after the initial test. After the initial test the arm ceased working because of unforeseen issues with the motor shaft. The final failure I encountered was at the competition itself. The arm housing which was supposed to be waterproof leaked after additional waterproofing the nights before, causing the ROV to weigh too much and sink.

This whole process was learning experience especially the failures. One of the first things I learned from my failures is to manage my time better. With the bid process I assumed I would be able to get my gear system with ease and it would be in the lab long before construction began, however I was wrong. I had issues with the process because I didn’t manage my time well enough so that I could constantly communicate back and forth with potential companies to procure a bid, causing me to lose bids and get no responses. I also learned the importance of time management from the failures of the final design, although I worked hard during the last few weeks leading up to the competition, I did work with the same drive for the whole marking period causing the final design to be rushed in construction causing issues with both the gear system and the waterproofing leading to the failures of each. Another thing I learned from my failures is to always keep trying and fixing your design, over a period of about three days my arm design stopped working and the waterproofing failed as well, after giving up on the arm I was I was given encouragement from my teammates and went back and tried to fix the failures to the best of my abilities.

I learned a lot by doing this project, and not just because of the failures I encountered either. One thing I learned a lot about was myself I learned how far I can push myself and how much I can handle under pressure and what attributes I have that are valuable and not so valuable. also learned a whole lot about engineering, which is good considering I might major in it. I learned about gear systems and the mechanics behind them and what allows them to function well. I also learned a lot about motors, how they worked, how much power they need, and even how some don’t need to be waterproofed if they are being used in fresh water. I learned a whole lot about wiring and motor controllers by helping my teammates with the control system. I also learned how to go through the design process from beginning to end. The process that I had to go through, although arduous and cumbersome at some points has defiantly opened my eyes up to what I will be dealing with in the real world, and how much more complicated things actually are. The final and most important thing I learned was that I do not want to be a mechanical engineer. Although I had one of the greatest experiences with this project I learned that mechanical engineering just does not suit me, mostly because of the issues I had with the construction of my design.

My final design had some significant design flaws that need to be addressed. The first is the waterproofing issue; the original concept was for the back half of the arm to be water tight because of the way the housing was put together. However I did not foresee the issues screws would cause with waterproofing, the screws did not seal the back half of the arm. Another problem with the waterproofing was the divider of the arm, this piece was also supposed to keep the back half of the arm dry, but improper cuts created a piece that did not fit snuggly in the arm. To fix these design flaws I would have either had to spend more time carefully waterproofing the arm with epoxy, or a better solution would be scraping the idea of a waterproof housing and just to waterproof the motor itself, which would mean there would be less areas that water could sneak in because the are to be waterproofed would be smaller. Another design flaw was the motor, the motor chosen was a small DC motor that ran at low voltage to save power and also low amperage, and how it ran too quickly. The motor spun the gear system too quickly for the system to function well, this flaw could have been fixed with a different motor that had a much lower rpm and a much higher torque than the motor originally selected. Another issue with the design was the gears, the gears that were used for the arm were hard plastic gears, however they were not able to be fastened easily to any rod to keep they suspended, this issue caused a discrepancy in the heights of the gears and cost numerous hours of work trying to get them close to the correct height. This flaw could have been solved by purchasing industrial gears that could be locked onto rods with a simple wrench and would stay in place much better than epoxy could ever hold the plastic gears.

This project was one of the most demanding ones I have ever undertaken and it helped improve my problem solving skills, my communication and teamwork, as well as my organizational skills. My problem solving skills were improved mightily during this project for a numerous reasons. The first was because of the design of my arm; I was tasked to design an arm that could perform three tasks within twenty minutes so right from the beginning of the project I was using my problem solving skills to try to make the design work. Another way my problem solving skills were improved was when the team was making last minute repairs to the ROV. During these repairs we were all faced with problems that had to be fixed on the fly causing us to think on our feet and solve all the issues on a tight time schedule. My communication skills improved vastly in this project. Public speaking was once a huge issue for me, but because of this project and the numerous presentations that I have been up through I have a new found confidence in public speaking almost to the point where I enjoy doing it, all thanks to lots and lots of practice. My communication skills have also improved in my drawings and designs for this project. It used to be that I never gave dimensions to drawings, but because of the project and the need for each part of the ROV to work together I dimensioned ever possible line or part of my design for my teammates, so they could understand the design better and so it could incorporate better with their designs as well. My communication through writing has also improved because of this project. The project requires you to both write in the technical style as well as a more normal style, and this change of style throughout the process kept me on the edge of my toes and kept me focused on what ever I writing was at hand. Also this project finally taught me how to cite photographs that were used in papers correctly, this is a valuable skill learned because later on in life it could end up being plagiarism if I continued to do it the incorrect way. Finally my communication between people improved as well. Working in a team forced me to communicate with them nonstop even if I didn’t want to at certain points. The project taught me how to convey my ideas and thoughts in a much more lucid manner making it easier for my teammates to understand me. This project improved my organizational skills by forcing me to plan out my work schedule months in advance and try to keep to that schedule by requiring commenting on my schedule almost daily. It also forced me to manage my time between the actual arm and the paper work and other things that were part of the class and the competition.

Overall this project was something that I enjoyed thoroughly and learned a lot from. This project pushed me very hard at points but at the same time taught me valuable life skills like better communication and organizational skills, as well as problem solving skills. I feel like I did not do as well as my design could have, and that was due to some of the design flaws as well as my laziness. If I had the chance to re do this project I would in a heart beat, because I had a lot of fun doing it as well and I learned a lot too.

Thursday, May 22, 2008

Testing

Expectations

The robotic arm is expected be able to grab, hold, and release objects retrieved in a pool ranging in depths from zero to four meters. The arm must be able to open and close its claw with ease and precision. The second function is grabbing objects. It must be able to grab any type of objects, ranging from either a light lattice structure sphere to a heavy PVC pipe. It also must be able to pick objects such as rope and thread it through a metal ring or rounded object. The arm should be able to open and close its claw and move in any direction.

Procedure

Before the ROV arm can be tested a few things must be done. First the arm along with the ROV must be transported to a pool that meets the specifications and limits that the ROV is given, one such pool in the one at Monmouth University. Along with the ROV arm the ROV is needed to test the arm, along with a heavy PVC pipe, a small light ball much like a rock crab, a PVC pipe with velcroed rocks.

1. Attach arm to ROV in less than five minutes

2. Test arm while out of water: do this by performing all functions of arm detached from ROV and out of water. The arm should be able to open and close its claw and move in any direction.

3. Once the arm has performed the task above, place the vehicle in the pool and allow the ROV to reach the maximum depth before beginning the next phase of testing. The arm should be able to open and close its claw and move in any direction

4. After basic tests have been completed, the arm now has to perform the tasks which the MATES competition has set down. Set rock crabs at the bottom of the pool and allow the arm to try to grasp them off the bottom of the pool.

5. Place the PVC pipe (with attached rocks) at the bottom of the pool, and allow arm to grasp rocks off of it. Once the rocks are grasped move the vehicle in all directions to test how well the arm holds the object while in motion.

6. The final task for the arm is for it takes the temperature of the vent by being able to place the attached thermometer near the vent.

7. The final step is for the ROV and arm to return to the surface and purge all the water, and check for any signs of water leaking into the system.

Testing Results

On April 26th, 2008 team Autobots took part in the New England Regional ROV competition. The team’s pool time was scheduled for 1:30, and prior to that there was a fifteen minute safety check that was required to gain access to the pool. During the safety inspection the ROV and all its components passed with flying colors including the robotic arm, the only issue was the fuse for the ROV was 30 amps not 25, so that issue was corrected. After passing the safety check the team proceeded to the pool area where it waited until its turn. Soon after arriving the team was able to take its turn; the team was able to set up in less than the five minute time, however there was an issue. The control system for the ROV was not working, causing the ROV to stay out of the water much longer than anticipated. Once in the water the ROV had control of only two of its motors, the only reason it sank was because the robotic arm filled with water, which was not in its design. At the bottom of the pool the ROV was able to move slightly but the arm was not in use because the motor would not turn (figure 1). At the bottom of the pool a net was used as a substitute for the arm, but this method also failed which can be seen in figure 2 and 3. To see the final scores please see the end of the paper.

Prior to the competition the arm was tested a couple of times. The first was without the motor system in place and by turning the worm gear the two helical gears turned as they were designed to. After the success of the test the motor and wiring for the Arm was put into place and the motor was tested without the gear system and it worked both in the forward and reverse motions. After all the components worked the arm was put together and tested out of water to see if it would work. When tested the motor would turn the gears as planned, however it would seize up every couple of turns of the motor shaft. The day before the competition the arm was tested again and the same results were collected, the motor would not turn.

In conclusion the arm design worked when tested by hand and worked momentarily however when all the components were put together it did not function as it was designed to. However the arm was assembled in less than five minutes used less power than it needed, and passed a safety check, all of which were part of its specifications or limitations.

Final Standings

ENG CRABS VENT POSTER REPORT BONUS TEAM NAME TOTAL PRIZE(s)

80 100 100 25.5 50.5 2.1* Blue Hills 358.1 1st Place, 1st Mission

88 70 100 38 54.5 NYCHEA 350.5 2nd Place, 1st Poster

84 90 100 27.5 40.0 Milton 341.5 3rd Place

74 70 100 25 30.5 Diman 299.5 Judge's Choice

92 50 100 18.5 38.6 Rogers 299.1 1st Engineering Eval

82 20 95 23 46.2 MAST 1 Deception 266.2

71 0 100 24 40.0 CRLS 235.0 Sharkpedo

86 0 0 32.5 60.5** MATES 179.0 1st Tech Report

62 40 0 18.5 47.8 BMC Durfee 168.3

56 40 0 18 51.3 SE Vo-Tech 165.3

73 30 0 23 39.0 Bristol CC 165.0

84 0 0 22.5 46.7 MAST 2 Autobot 153.2 Guts & Glory

66 0 0 24 52.0 Sound School 142.0

69 0 0 18 39.9 Weaver 126.9 Team Spirit

100 100 100 40 60.0 10.0 410.0 (TOTAL POSSIBLE)

* 2.1 points for pool time bonus

** 0.5 bonus points after average

Tuesday, April 29, 2008

MP4 Calendar

Week of April 28- May 2

28. Start and finish MP4 calendar, work on power point for Friday

29. Work power point at home, update blog

30. NO CLASS, Finish Power point at home

1. Work on testing and results

2. Not in School, update blog

Week of May 5-9

5. Work on testing and results

6. Work on testing and results, update blog

7. Work on testing and results

8. Finish testing and results and hand it in to teacher

9. Start self evaluation, update blog

Week of May 12-16

12. Continue work on Self evaluation

13. Continue work on Self evaluation, update blog

14. Presentations, Hand in self evaluation

15. Presentations

16. Presentations, update blog

Week of May 19-23

19. Fix and add to presentation board

20. Fix and add to presentation board, update blog

21. Fix and add to presentation board

22. Finish Board, Presentation Night

23. Start Mentor contacts, update blog

Week of May 26- 30

26. Work on mentor contacts

27. Work on Final update blog

28. Work on Final

29. Work on Final

30. NO SCHOOL, update blog

Week of June 2- 6

2. Work on Final

3. Work on Final, and work on mentor contacts, update blog

4. Work on Final, update mentor, and hand in mentor contacts

5. Work on Final

6. Work on Final, update blog

Week of June 9-13

9. Work on Final

10. Work on Final

11. Finals

12. Finals

13. Finals

Week of June 16- 17

16. Finals

17. GRADUATION!!!!!!!

Monday, April 7, 2008

Tuesday, February 5, 2008

Calendar MP3

Week of February 4-8

4. Continue work on MP3 calendar, after finishing it, hand it in

5. Update blog, correct midterm, and send it to mentor

6. Construction- start to mark and measure all items that will be made of lexan

7. Construction-finish all marking and measuring; cut out base pieces.

8. Construction- finish cutting base, start cutting sides, sand sides and bottom; update blog

Week of February 11-15

11. Construction- Finish sanding sides, and perform a dry fit of materials

12. Construction- After performing dry fit makes any corrections needed; start on drilling holes, update blog and mentor

13. Construction- continue drilling holes.

14. Construction- Finish drilling holes.

15. Construction- Run dry fit of all pieces update blog and mentor

Week of February 18-22

18. NO SCHOOL

19. Construction- start measuring and cutting claws, update mentor, and update blog.

20. Construction- Cut and sand claws to proper size.

21. Construction- Sand claws, and mark holes on the claws

22. Construction- Run dry fit of all materials, making any corrections where needed, update blog and mentor

Week of February 25-29

25. Construction- Place rods and through gears, and secure them together tightly, place gears with rods on base, for dry fit.

26. Construction- create motor support, update blog

27. Construction- continue work on the motor support

28. Construction- place motor on support and make any corrections if needed.

29. Construction- drill pilot holes for screws in all pieces of lexan, update blog and mentor

Week of March 3-7

3. Construction- screw top of the arm to the rest of the arm, make any corrections where needed.

4. Construction- Attach plastic rod to shaft of motor and run a trial of the gear system, update blog

5. Construction- Make any corrections to gear system fro previous day, and run another trial

6. Construction- Attach claws to gears, and assemble the whole arm.

7. Construction-Run trial of completed arm making any corrections needed, update blog and mentor

Week of March 10-14

10. Construction- finishes any adjustments and run a trial under water

11. Update blog, Construction- Make any corrections after trial run in water, and perform another trial

12. Construction- make any corrections after water trial, attach arm to ROV

13. Construction- attach arm to ROV and run tests

14. Start Press release, update blog and mentor

Week of March 17- 21

17. Work on press release

18. Update both blog and mentor, POOL DAY- prepare for pool day

19. Fix any problems that arose at pool test, finish press release.

20. Make any corrections to ROV after pool test.

21. NO SCHOOL

Week of March 31-April 4

31. Start presentation outline.

1. Finish presentation outline, and work on mentor contacts, update blog

2. Finish mentor contacts and prepare for pool test, update mentor

3. PRESENTATIONS- Hand in mentor contacts

4. PRESENTATIONS and pool day

Week of April 7-11

7. PRESENTATIONS

8. Fix problems from last pool day; prepare for new pool day, update blog

9. Make corrections from yesterday’s pool test

10. Prepare for pool day

11. Make corrections for last pool test, update blog

Thursday, January 17, 2008

Wednesday, January 16, 2008

Math and Science Report

One of the most integral parts of the capstone design project is the math and science background of each design. Each design has some backing in either Science or Math which allows it to perform its designated function. My capstone design project, a robotic arm for the MATES competition, has both mathematical and scientific backgrounds which are an important part of the design and solution choices

Technology

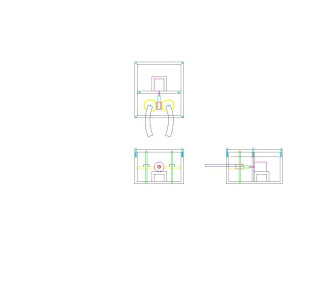

Before explaining the science and math concepts that are involved the arm, you must first talk about the technology aspect of it. There are two primary forms of technology in my project, the motor (Fig.1-2) and a material called

Science

The main category of science that my arm incorporates is physics. Physics is the science studying the concept of matter and its motion, as well as space and time the science that deals with concepts such as force, energy, experimental science, and it is the objective of physicists to understand some quality of the natural world. Although the study of physics encompasses the vast areas of study stated above, my project only focuses on the areas or force, mass, and motion. The first and possibly most important part of the arm is the torque which it produces. Torque is a measure of how much force acting on an object causes that object to rotate. In my arm this applies to the amount of torque the gears are producing when the motor  is active. To find the torque that arm produces, a few factors must be known. Before the torque can be calculated the gear ratio must be found. A gear ratio (Fig.1-1) is simply the output gear number of teeth / the input gear number of teeth, calculations for gear ratio can be found further on in the report. After finding the gear ratio the torque of the arm can be found. To find the torque with regards to the arm the following equation is used: Motor Torque x gear ratio = torque at the wheel; calculations for arm torque can be found further on in report. Another important calculation regarding arm is the speed at which the gears turn; another physic related problem. To find the speed at which the gears in the arm move is a simple law. The gears speed are relative to each other, therefore the gear ratio determines the speed (seen above) of each gear in relation to each other. For example if the input gear (10 teeth) is rotating at 5 rpms, and it is connected to our output gear (50 teeth), the output gear will rotate at 1 rpms. The relationship for the gears speed is 48 to 1. This is true because for every one turn of the worm gear the worm revolves 48 times.

is active. To find the torque that arm produces, a few factors must be known. Before the torque can be calculated the gear ratio must be found. A gear ratio (Fig.1-1) is simply the output gear number of teeth / the input gear number of teeth, calculations for gear ratio can be found further on in the report. After finding the gear ratio the torque of the arm can be found. To find the torque with regards to the arm the following equation is used: Motor Torque x gear ratio = torque at the wheel; calculations for arm torque can be found further on in report. Another important calculation regarding arm is the speed at which the gears turn; another physic related problem. To find the speed at which the gears in the arm move is a simple law. The gears speed are relative to each other, therefore the gear ratio determines the speed (seen above) of each gear in relation to each other. For example if the input gear (10 teeth) is rotating at 5 rpms, and it is connected to our output gear (50 teeth), the output gear will rotate at 1 rpms. The relationship for the gears speed is 48 to 1. This is true because for every one turn of the worm gear the worm revolves 48 times.

Another important part of the arm is the pressure the claws produce on the object that is being grabbed. Pressure is the application of continuous force by one body on another that it is touching; compression. Pressure is important because if the claws can not apply enough pressure onto the object, they will not be able to hold it; or if they apply to much pressure the object will either break( near impossible with this design) or if the pressure isn’t equally applied from each claw the object could slip out of the arms grip. To calculate the pressure that arm will produce you perform the following equation: force (torque in this case) / area of the object; (pressure

calculations further in report).

calculations further in report).

The most complex component in the arm is the motor (Fig.1-2) that drives the arm. Every DC motor has six basic parts -- axle, rotor, stator, commutator, field magnet(s), and brushes. In most common DC motors, the external magnetic fie ld is produced by high-strength permanent magnets. The stator is the stationary part of the motor -- this includes the motor casing, as well as two or more permanent magnet pole pieces. The rotor (together with the axle and attached commutator) rotates with respect to the stator. The rotor consists of windings (generally on a core), the windings being electrically connected to the commutator (Fig.1-3). The above diagram shows a common motor layout -- with the rotor inside the stator (field) magnets. Considering the motor being used was purchased rather than built, no calculations to make because the motor comes along with its numerical data. The voltage range of the motor is 1.5-4.5 volts, with the nominal voltage at 3, the rpm at nominal load is 8700, the rpm at normal load is 6400, and the current at no load is 190 milliamps.

ld is produced by high-strength permanent magnets. The stator is the stationary part of the motor -- this includes the motor casing, as well as two or more permanent magnet pole pieces. The rotor (together with the axle and attached commutator) rotates with respect to the stator. The rotor consists of windings (generally on a core), the windings being electrically connected to the commutator (Fig.1-3). The above diagram shows a common motor layout -- with the rotor inside the stator (field) magnets. Considering the motor being used was purchased rather than built, no calculations to make because the motor comes along with its numerical data. The voltage range of the motor is 1.5-4.5 volts, with the nominal voltage at 3, the rpm at nominal load is 8700, the rpm at normal load is 6400, and the current at no load is 190 milliamps.

The final piece of science that the arm incorporates is the actually gears used to make the arm work. The gear drive that is being used in the arm is called a worm drive; this drive is comprised of two parts (Fig.1-4). The

first part is the worm, a screw like gear that has one tooth (Fig.1-4). The second part is the worm gear, this a circular gear that is very much like a helical gear, and these can range in tooth size, as long as the pitch remains the same between the gears. The purpose of a worm drive is to increase the torque a drive can produce, which is why this particular drive is perfect for the arm.

first part is the worm, a screw like gear that has one tooth (Fig.1-4). The second part is the worm gear, this a circular gear that is very much like a helical gear, and these can range in tooth size, as long as the pitch remains the same between the gears. The purpose of a worm drive is to increase the torque a drive can produce, which is why this particular drive is perfect for the arm.

![]()

The newest and most advanced part of the arm design, is one of the materials being used in the construction of the arm, Lexan.

Math Calculations

Gear Ratio:

Number of teeth on worm: 1

Number of teeth on worm gear: 48

Gear Ratio: 48:1

Torque:

Motor Torque= (Hp*5252)/RPM,

HP= (V*I*Efficiency)/ (746)

HP= (3*1*.82)/ (746)

HP= .00329

Motor Torque= (.00329*5252)/8700 (nominal load rpm)

Motor Torque= .0019906

Gear Ratio= 48

Torque= Motor Torque * Gear Ratio

T= .0019906*48

T= .095

Pressure:

Force= Torque= .095 N

Area of Claw= L*W

A= .25inches*.25inches

A= .0625 icnhes^2

P= .095*.0625

P= .00597 PSI

Conclusion

So in conclusion, that my capstone design project encompasses a good deal of science and math. Whether the science is the gears or the motor, it all plays a crucial element in the overall effectiveness of the design. The mathematical calculations although simple have a great impact on the effectiveness of the arm. Overall the ROV arm requires a great deal of scientific evidence and mathematical calculations to make the arm successful, and the information presented in this report is the proof of that evidence.

Plan Of Procedure

Plan of Procedure

- Gather all materials listed in the above tables, and bring them to the working area

- Gather all measuring and marking material and bring them to the working area

- Measure, mark, and layout all sides of outer box.

- Make sure all layout lines are within 1/16th of the specs for each piece

- Cut all marked pieces on band saw and cut to specifications

- After cutting each piece number and code each piece to avoid confusion.

- Perform a dry fit for all pieces to assure all pieces fit together

- Make any corrections, if needed, after doing the dry fit.

- Take bottom and top labeled pieces and mark on each the areas where holes will be drilled.

-

Take drill and drill bit and mark on drill a quarter inch from the tip of the d rill bit.

rill bit. - Slowly drill marked area making sure not to exceed marked depth on drill bit.

- After drilling first hole, change drill bit to and again mark a quarter inch up from the top of the drill bit with tape (Fig.1-1).

- Repeat step 11 with larger drill bit, making sure to bevel the hole.

- After drilling the holes on both the top and bottom pieces, run a dry fit with the plastic rods rods, and the drilled holes (Fig1-2).

- Make any corrections needed after this dry run.

- Mark all points on the labeled pieces for pilot holes.

-

After marking all points on pieces take drill with drill bit, and mark depth of screw on the drill bit. - Slowly drill each hole, making sure not to shatter the polycarbonate.

- After drilling each hole take drill bit and again mark length of screw from the tip of the drill bit.

- Using new drill bit size; continue drilling each marked area to marked depth on the drill bit, making sure not to shatter the polycarbonate, and to bevel each hole(Fig1-3).

- After drilling each hole assemble the pieces including the plastic rods to ensure a firm fit of all the pieces.

- Make any corrections if needed.

- Mark on polycarbonate the specifications for the interior divider

- Make sure all measurements are within 1/16th of an inch, of computer drawings.

- Cut piece using band saw, cut to specifications

-

Code piece after cutting - One bottom and top piece mark area in which the divider will be placed

- After marking the top and bottom pieces do a dry fit with the divider in the box.

- Make any corrections if needed.

- Print out copy of full scale claw of the arm

- Tape printed out claw onto remaining polycarbonate.

- Using thick permanent marker trace the claw onto the polycarbonate.

- Measure dimensions on polycarbonate, to ensure they are within 1/16th inch,

make and corrections if need.

make and corrections if need. - Using band saw, make outline cuts of the claw, leaving space so it can be sanded down to final form.

- Wearing a mask, and in a ventilated area sand the cut out claw pieces, starting with the coarsest sand paper and working towards the finest.

- After sanding claws down to final form, mark on each the area where a hole will be placed for the plastic rods (Fig1-4).

- Measure hole to make sure it is within a 1/16th of an inch of specifications.

- Take drill and appropriate size drill bit and drill hole, making sure not to shatter Lexan, in

appropriate area (Fig1-5).

appropriate area (Fig1-5). - After drilling do a dry run with the plastic rods and claws, make corrections if needed.

-

Now assemble motor support by marking the dimensions of the unit on the last of the Lexan. Re-measure to assure accuracy of dimensions.1-5

- Cut out marked and dimensioned pieces on the band saw.

- Run dry fit of pieces, making corrections if needed.

- Mark and measure the area in which the hole for the shaft of the motor will be placed.

- Using drill and appropriate drill bit, drill hole in correct area on the divider.

- Take the largest plastic rod, and center it on the shaft of the motor.

- After repeatedly centering it and marking each centering on the plastic rod, take a drill bit (1/16th) and measure up from the tip of the drill bit a half an inch( length of shaft), and mark it with tape.

- Slowly drill the hole on the center mark of the rod, making sure it does not shatter.

- After completing the hole, run a dry fit, making corrections where needed.

- With all components completed run a full scale dry fit, making corrections where needed.

- After corrections have been made, start to assemble the arm.

- First start with gluing the bottom of the box to the sides of the box, using the special polycarbonate glue, Ploy Zap.

- After completing that, attach back to the bottom, using the same method stated above.

- Then attach divider to the bottom using the same method as above.

- Assemble motor support using same method as sated above and then attach it to the bottom, using same method.

- Place motor on motor support, making sure to align shaft perfectly with hole in the divider.

- Attach worm gears to their respective support rods.

- Attach Connecting rod to shaft, making sure it is centered, then place connecting rod, into bore of the worm, and connect them together.

- Place plastic rods (with gears attached), into their perspective holes, and grease the holes with WD-40(Fig1-6).

-

Carefully place top onto ROV, making sure that while screwing it in, nothing is shattered. - Touch any looser ends

Lists

| Supply List | ||||

| Item | Description | QTY | Size | Remarks |

| 1 | WD-40 | 1 | 12 oz | To lubricate metal rods |

| 2 | Tape | 1 | One roll | To mark drill bit |

| 3 | Sandpaper- Coarse | 2 | 12”x 12” | Sand lexan |

| 4 | Sandpaper- Medium | 2 | 12”x12” | Sand lexan |

| 5 | Sandpaper- Fine | 2 | 12”x12” | Sand lexan |

| 6 | Polyzap | 6 | 2 oz | Glue lexan |

| Tools and Equipment List | ||

| Item | Description | Use |

| 1 | Band Saw | Cut Lexan |

| 2 | Screws | Secure walls |

| 3 | Drill | To drill into bottom and top pieces |

| 4 | Drill Bits | Drill holes in lexan |

| Material List | ||||

| Item | Description | QTY | Size | Remarks |

| 1 | Helical Gear | 2 | 1.75 inches (OD) | For drive of Arm |

| 2 | Worm | 1 | Face Width .75 inches | Drive of Arm |

| 3 | Motor | 1 | Dia: 1 Inch, L: 1.25” | Drive of Arm |

| 4 | Lexan | | 12”x14” | Claw and casing material |

| 5 | Plastic Rod | 2 | H: 2.5” Dia: 1/8” | Stabilizers for gears |

| 6 | Plastic Rod | 1 | L: 1.25” Dia: .25” | Connection between shaft and Worm |

| 7 | Screws | 6 | L: .75, Phillips head, ¾ threaded | Securing top piece of lexan to rest of arm |