- The maximum surface power of the vehicle will be no greater than 13 volts, 25 amps

- The vehicle must operate on DC voltage

- there will be no on board power except for the lights

- the vehicle will have three monitors

- the vehicle must be able to be moved without the aid of electrical powered devices

- ROV must be able to dive and surface in a tank no deeper than 4 meters

- Number of people required is 3

- the vehicle must be able to operate in waters between -1 degrees Celsius and 18 degrees Celsius

- the project will require 8 months of design and construction.

- Hydraulics must not exceed 150 psi.

- Pneumatics must not exceed 40 psi.

- The Rov will be controlled and powered through a tether.

- No onboard power supply is allowed except for lights that use 9 volts or less.

- Tools: Wire cutters, Soldering gun, Wire Strippers, band saw, and welding equipment ( possibly)

- Information: propulsion, buoyancy, robotics, electronics, circuitry, and hydrodynamics.

- Materials: aluminum, PVC, copper wires, insulation for wires

- Capital: anywhere between 500 dollars to 1000 dollars, it all depends on the materials used

Sunday, September 23, 2007

Limitations

Specifications

- Electrical components must be properly waterproofed.

- The Rov arm must be able to operate at depths up to 4 meters.

- The Rov arm must be capable of running in fresh, chlorinated water.

- The Rov arm must be able to grab both small and large items.

- The Rov arm must be strong enough to hold at least ten pounds underwater.

- The Rov arm must use as little power as possible.

- ROV arm will be remote controlled

- The arm must pass a safety check and be able to be assembled within 5 minutes

Thursday, September 20, 2007

Testing

The robotic arm is expected be able to grab, hold, and release objects retrieved in a pool ranging in depths from zero to four meters. The arm must be able to open and close its claw with ease and precision. The second function is grabbing objects. It must be able to grab any type of objects, ranging from either a light lattice structure sphere to a heavy PVC pipe. It also must be able to pick objects such as rope and thread it through a metal ring or rounded object. The arm should be able to open and close its claw and move in any direction.

Before the ROV arm can be tested a few things must be done. First the arm along with the ROV must be transported to a pool that meets the specifications and limits that the ROV is

given, one such pool in the one at Monmouth University(right). Along with the ROV arm the ROV is needed to test the arm, along with a heavy PVC pipe, a small light ball much like a wiffle ball, and a rope and metal circle.

given, one such pool in the one at Monmouth University(right). Along with the ROV arm the ROV is needed to test the arm, along with a heavy PVC pipe, a small light ball much like a wiffle ball, and a rope and metal circle.Steps

1. Attach arm to ROV in less than five minutes

2. Test arm while out of water: do this by performing all functions of arm detached from ROV and out of water. The arm should be able to open and close its claw and move in any direction.

3. Once the arm has performed the task above, place the vehicle in the pool(right) and allow the ROV to reach the maximum depth before beginning the next phase of testing. The arm should be able to open and close its claw and move in any direction.

4. After basic tests have been completed, the arm now has to perform the tasks which the MATES competition has set down. To simulate these, place the PVC pipe at the bottom of the pool, and allow arm to grasp it. Once the pipe is grasped move the vehicle in all directions to test how well the arm holds the object while in motion.

5. Place the PVC pipe at the bottom of the pool, and allow arm to grasp it. Once the pipe is grasped move the vehicle in all directions to test how well the arm holds the object while in motion.

6. The final task for the arm is for it to grab the rope at the bottom of the pool and see if it can place it through a metal hoop. Test this by grabbing a previously placed rope with the arm. Then move the arm with clasped rope in hand to the loop which is placed at the bottom of the pool and proceed to thread it through the loop(below).

7. The final step is for the ROV and arm to return to the surface and purge all the water, and check for any signs of water leaking into the system.

First photograph courtesy of SD and LB

"ROVs Pg2." MATE 6th ROV Competition 2007. MATE. 28 Sep 2007. http://www.marinetech.org/rov_competition/2007/results/Photos/ROVs%20Pg%202.html

"ROVs Pg3." MATE 6th ROV Competition 2007. MATE. 28 Sep 2007 http://www.marinetech.org/rov_competition/2007/results/Photos/ROVs%20Pg%203.html.

Background Information

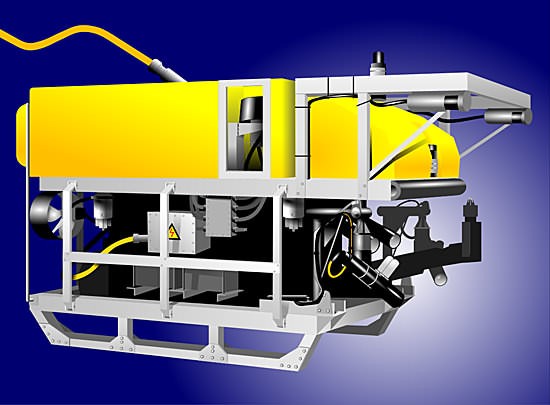

play a key role in the advancement of the world’s economy; one of those machines is the ROV(right).

play a key role in the advancement of the world’s economy; one of those machines is the ROV(right). A key component to the ROV is its robotic appendage. Whether the appendage is an arm, claw, or some other attachment; they all perform similar tasks. In 1962 the first industrial arm robot - the Unimate - is introduced. It is designed to complete repetitive or dangerous tasks on a General Motors assembly line; this was the start of a new age of technology. Then in 1969 only seven years after the first robotic arm was invented Victor

Scheinman, a Mechanical Engineering student working in the St

anford Artificial Intelligence Lab (AIL) creates the Stanford Arm (right). The arm's design becomes a standard and is still influencing the design of robot arms today. Five years After Victor Scheinman created the Stanford Arm, he starts his own company and starts selling the Silver arm, which can put together small parts. In 1981 Takeo Kanade builds the direct drive arm. It is the first to have motors installed directly into the joints of the arm. This change makes it faster and much more accurate than previous robotic arms.

anford Artificial Intelligence Lab (AIL) creates the Stanford Arm (right). The arm's design becomes a standard and is still influencing the design of robot arms today. Five years After Victor Scheinman created the Stanford Arm, he starts his own company and starts selling the Silver arm, which can put together small parts. In 1981 Takeo Kanade builds the direct drive arm. It is the first to have motors installed directly into the joints of the arm. This change makes it faster and much more accurate than previous robotic arms. situation whether it is from heavy lifting to precise movements of objects the appendage must be able to handle the work load.

situation whether it is from heavy lifting to precise movements of objects the appendage must be able to handle the work load.Design Brief

Wednesday, September 19, 2007

MP1 Calender

Week of September 17-21

20. Hand in completed calendar; finish corrections on portfolio, post corrections on blog, and start to redo drawings

21. Continue work on drawings for presentation

Week of September 24-28

24. Finish drawings for robotic arm, scan drawings and send them to mentor

25. Update blog and calendar, start to redo 3d drawings

26. Continue work on 3d drawings, update mentor on progress

27. Finish 3d drawings of arm; send completed drawings to mentor, upload drawings to blog

28. Start preparation for informal presentation, start outline for presentation

Week of October 1-5

1. Finish preparation for presentation, finish outline, update blog

2. Contact mentor for status update, practice for presentation

3. Presentation, hand in Outline and up to date web blog

4. Presentation

5. Presentation

Week of October 8-12

8. Start selection rejection report

9. Continue work on selection rejection report, focusing on imagery for it, update blog

10. Work on the pros and cons of solution one of selection rejection report

11. work on second solutions pros and cons for report

12. work on third solutions pros and cons for report, update blog

Week of October 15-19

15. Finish up selection rejection report and up date mentor on progress

16. Make final corrections and upload selection rejection to blog, update calendar on blog

17. Start to design model, layout all materials needed to create model

18. Start to measure and materials need for model and begin to cut them to size

19. Finish measuring and cutting all materials for model, update blog

Week of October 22- 26

22. Start to attach materials to each other, and contact mentor for update on progress of project

23. Continue to assemble model, update blog

24. Continue with the assembly of model

25. Finish assembly of model, take pictures of it and send to mentor

26. Update blog; start to prepare blog for formal presentation

Week of October 29- November 2

29. Start outline for formal presentation

30. Update blog, continue work on outline, and prepare for presentation

31. Hand in outline, mentor contacts, selection rejection report, and model

1. Presentations

2. Presentations

Week of November 5-9

5. Presentations

6. Update both blog and mentor

7. Start new calendar for MP2

8. Start developmental work

9. Start developmental work

Week of November 12-13

12. Start developmental work

13. Start developmental work